After getting the tire temperature sensor modules working, the next thing I wanted to measure was brake disc temperature. This felt like a natural next step. Braking is one of the most aggressive actions on a motorcycle, and I was curious to see how quickly heat builds up during real riding.

At first, this part of the project seemed like it would be straightforward.

Using the same sensors

For brake disc temperature, I reused the same non-contact infrared temperature sensors I had already used for tire temperature sensing. The advantage of these sensors is that they measure temperature by detecting infrared radiation from a surface, which means there’s no need for physical contact.

That immediately simplified things.

No drilling, no clamps on brake lines, no risk of interfering with braking hardware.

In theory, I just needed to point the sensors at the discs and read the temperature.

Front brake disc mounting

The first challenge was mounting. I needed to position the sensors so they were:

- Facing the brake discs directly

- At a reasonable angle

- Stable under vibration

For the front brakes, this meant aiming one sensor at the front-left disc and another at the front-right disc. Getting the angle right mattered more than I initially expected. Small changes in alignment noticeably affected readings.

By this point in the project, I was also dealing with a familiar limitation.

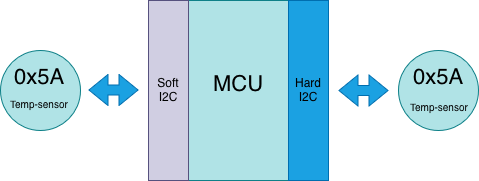

The I2C address problem (again)

All the infrared sensors I had left used the same fixed I2C address (0x5A). That meant I couldn’t place both front brake sensors on the same I2C bus.

The solution was the same workaround I had used before:

- One sensor on the hardware I2C bus

- One sensor on a software-emulated I2C bus

It wasn’t elegant, but it worked. Once everything was wired up and programmed, I could read temperature data from both front brake discs reliably.

Rear brake disc sensing

The rear brake disc was much simpler. I only needed a single sensor, which meant I could use the hardware I2C bus without any address conflicts.

Mounting the rear sensor was easier as well, though I quickly noticed that sensor distance mattered. The further the sensor was from the disc, the slower and less responsive the temperature readings felt. In hindsight, I could have mounted it closer, but for an early version of the system, it was good enough.

Once mounted, I could clearly see surface temperature changes on the rear brake disc during riding.

Why non-contact sensing mattered

One of the biggest advantages of using infrared sensors here was that I could measure brake disc temperature without touching the disc at all.

The sensors picked up infrared radiation emitted by the metal surface, which meant:

- No risk of interfering with braking

- No heat damage to wiring

- No moving parts to worry about

It wasn’t laboratory-grade measurement, but it was more than enough to show real trends—especially during hard braking.

Software stayed simple

By this stage, I had settled on a consistent software structure for all sensor modules. Each module followed the same basic pattern:

- Read sensor data

- Package it into a simple data format

- Send it back over WiFi using UDP

The brake disc temperature modules reused the same approach. From the data logging side, nothing special was needed. The logging program simply listened for incoming packets and stored everything into a log file.

Because of this consistency, adding brake disc temperature sensing was relatively easy compared to earlier stages of the project.

What this stage confirmed

This part of the project reinforced a few important lessons:

- Reusing a known sensor design saves time

- Physical mounting and distance affect readings more than expected

- Non-contact sensing is extremely useful on a motorcycle

- Software simplicity becomes valuable as the system grows

Brake disc temperature sensing worked well enough to answer the questions I had, and it gave me confidence to keep expanding the system.